Latest news and resources on 3D scanning and measurement technologies

While 3D scanners can scan most objects without a hitch, there are some surfaces that are more challenging to scan. These type of surfaces include dark, shiny, and transparent surfaces. This article provides tips on how to make it easier to scan these difficult parts with video demonstrations.

Read Article ⟶

Weistec Engineering is a the leader in research, development, and design of fast and reliable parts and accessories for Mercedes AMG. Based in Santa Ana, California, the company keeps nearly every aspect of conceptual 3D design and development, manufacturing process, and road and tracking in-house to insure the highest quality. Creating high performance quality product is a must.

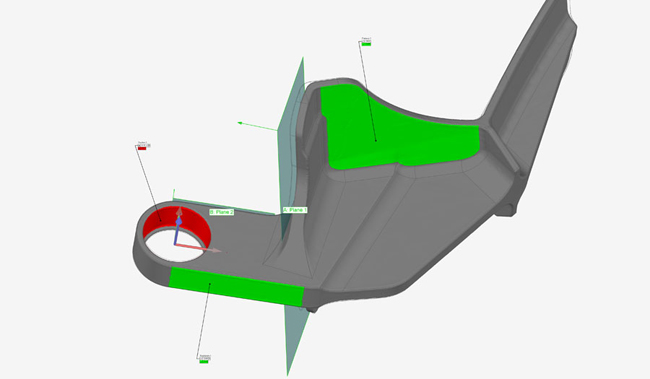

Learn how Weistec Engineering implemented a cost-effective Scan-to-CAD process for reverse engineering that saves valuable time.

Discover Now ⟶

With continuous advances in optical inspection technology yielding 3D scanners that are today capable of stunning speed and accuracy, a growing number of companies are including this technology in their first article inspection (FAI) procedures. This Quality Magazine article explains what is first article inspection, what the process looks like, and how implementing this type of inspection process will benefit your organization.

Read More ⟶Our team at GoMeasure3D is always looking for the best 3D technologies to transform the way you work. We recently introduced two cost-effective solutions for computer-aided inspection.

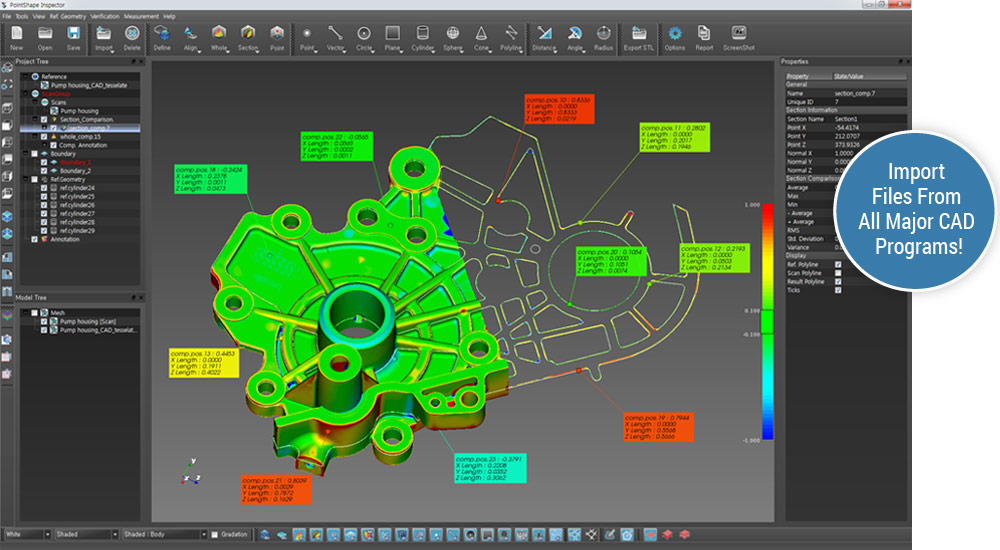

PointShape Inspector provides you with all the tools to have complete control over the inspection process by comparing scan data to CAD. Implementing this platform ensures your products are manufactured of the highest quality standards. It reduces time and cost with a simple workflow, user friendly interface, and precise calculation.

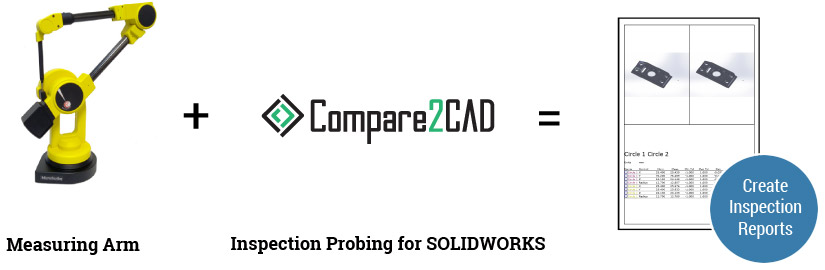

Compare2CAD works seamlessly with major measuring arms to deliver an integrated computer-aided inspection solution inside SOLIDWORKS. Work with the original tool you use for your design. There’s no need to import or export your SOLIDWORKS models which can be a hassle.

A company’s quality control team is only as good as the tools it has available to work with. Given this, handheld 3D scanning technologies have become essential for quality control operations within industrial settings. Learn how advancements in handheld 3D scanners is freeing up valuable labor hours and offering flexibility into the quality control process.

Read Article ⟶

We deliver 3D scanning and measurement solutions that transform real world objects into digital 3D models for industry applications including CAD/CAM, reverse engineering, quality inspection, scientific measurement, and 3D visualization. If you have any questions related to 3D scanning or 3D measurement technology, ask our technical specialists and they would be happy to help you out.