Overview

The Artec Space Spider has the highest stated accuracy out of all the Artec handheld 3D scanners. With its superior precision, long-term repeatability in data capture, and automatic temperature stabilization, the device is the perfect solution for metrology applications that require high-precision 3D scanning of small objects with sharp edges and intricate details.

The Artec Space Spider has the following stated technical specifications.

Datasheet Specifications

Accuracy:

Closeness to the Real Value

up to 0.05 mm

(~0.0020”)

Resolution:

Distance between two points

up to 0.1 mm

(~0.0040”)

What happens to the accuracy of the Artec Space Spider when 3D scanning challenging objects? How would the handheld 3D scanner perform under these extreme situations?

Accuracy is very important in the world of metrology, especially for quality inspection applications. Our team underwent two separate accuracy tests to see how the Artec Space Spider will fare when 3D scanning tricky parts. We used objects with known measurements so we can compare how the scan measurements deviate from the accuracy, the true measurement. We will then compare the accuracy of our tests to the accuracy number of the datasheet.

It might seem contradictory but there’s a lot of complexity when it comes to scanning very simple parts. That’s because they are the most difficult for a 3D scanner to scan.

Parts that are the most challenging for optical 3D scanners include:

- Flat and square objects (i.e. 1-2-3 block in our first test)

- Long smooth objects (i.e. ballbar in our second test)

- Flat reflective objects

The reason why these types of objects are difficult to scan is due to their lack of characteristics such as features, texture, and color. 3D scanners rely on an object’s unique geometry to align overlapping digital scans into a complete model.

The scan objects we use in these tests are not what you would scan in normal situations. We wanted to push the Artec Space Spider to its limits and see what would happen.

For all our tests, we use the Artec Space Spider with its companion 3D scanning software, Artec Studio 15.

Test 1

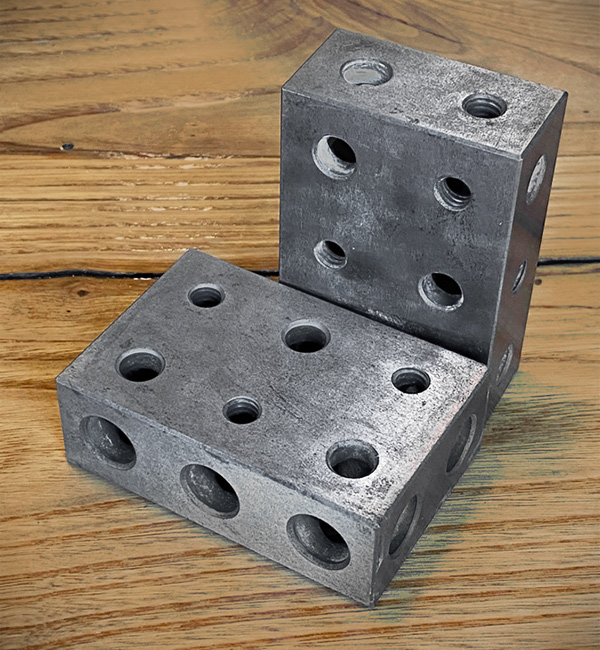

3D Scanning 1-2-3 Block

(Flat and Square Object)

This is a great test in terms of accuracy and alignment performance of the Artec Space Spider and Artec Studio 15.

Each side of the block is precisely square and parallel to each other. Given that 1-2-3 blocks are accurately ground to within .005mm (or .0002”), you can use them for quality inspection or for zero your measuring tools.1

What makes 3D scanning a 1-2-3 block so difficult to scan?

A 1-2-3 block is flat, uniform, and parallel on both sides.

It also lacks:

- External reference geometry

- Texture

- Color (It only has one color)

This makes it very difficult for the 3D scanner to align the scans into a complete digital 3D model and get repeatable results.

Criteria For This Test

When aligning the scans into a complete digital 3D model, we used no external geometry or texture for reference. This means even the table surface or any background surfaces were taken out prior to aligning the scans.

The testing procedures must be repeatable between people. Therefore, we used three different people to conduct the testing. The reason we used different people to conduct the experiment was to make sure the results were repeatable even if the people conducting the tests varied.

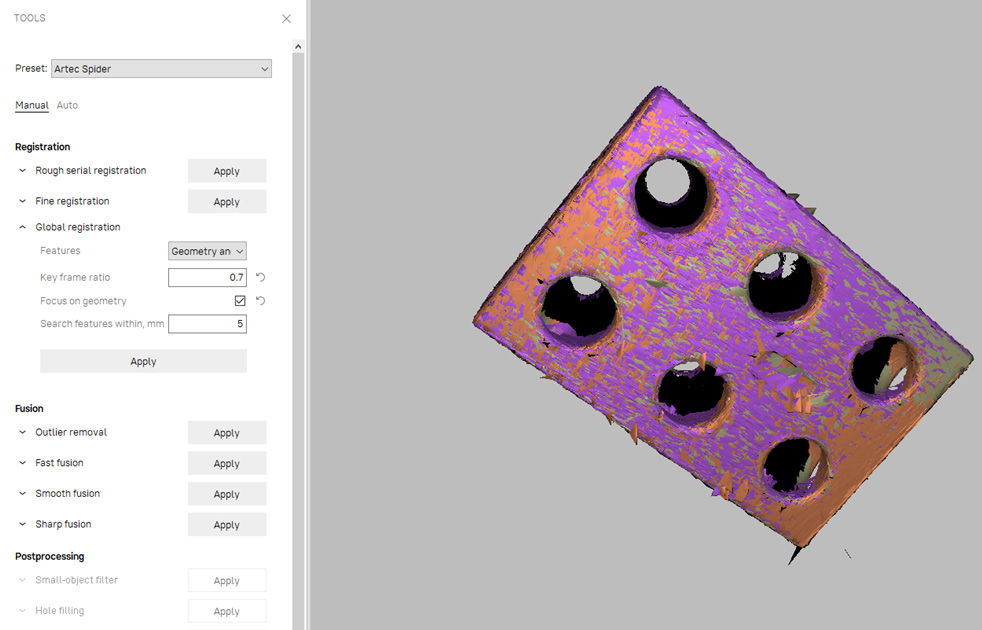

Testing Procedures

The procedures were conducted 6 times at different times over several days by 3 different people.

Each time, the object was scanned using these procedures:

- Three distinct scan orientations

- Full 360 degree Scan Global Registration

- Key frame ratio of 0.5-0.7

- Two iterations of Global Registration and Outlier removal

* Note: We find that through our many years of using the Artec 3D scanners, the above parameters output the best 3D scanning results.

We processed the data out of Artec Studio 15 with a 0.3 mm resolution. The results were analyzed inside Geomagic Control X and the deviation are outlined in an Excel spreadsheet for further analysis.

Test Results: Space Spider GR&R for 1-2-3 Block

| Tests | Deviation (in inches) | |||

|---|---|---|---|---|

| 1″ | 2″ | 3″ | Flatness | |

| JPS1 | 0.0013 | 0.0001 | 0.002 | 0.0004 |

| JPS2 | 0.0005 | 0.0014 | 0.0018 | 0.0002 |

| AAS1 | 0.0023 | 0.0012 | 0.0026 | 0.0004 |

| AAS2 | 0.0004 | 0.00013 | 0.00018 | 0.0003 |

| PMS1 | -0.0019 | 0.0003 | 0.0022 | 0.0005 |

| PMS2 | -0.0019 | 0.00023 | 0.0008 | 0.0004 |

| Standard Deviation | 0.00170 | 0.00058 | 0.00092 | 0.00010 |

| Max Deviation | 0.0023 | 0.0014 | 0.0026 | 0.0005 |

| Average | 0.00012 | 0.00056 | 0.00160 | 0.00035 |

| Max From Average | 0.00218 | 0.00084 | 0.00100 | 0.00015 |

Key Statistics

- Max Deviation (from any side): 0.0026” (0.06604 mm)

- Max From Average (from any side): 0.00218”(0.055372 mm)

- Flatness (from any side): 0.0005” (0.0127 mm)

Video Recap

Here’s a video recap of the tests and the results:

Findings

When you are dealing with worst case scenario type applications such as scanning a 1-2-3 block, we still achieve tight accuracy numbers when looking at the deviation values.

When we’re looking at the max deviation 0.06604 mm compared to the accuracy “up the 0.05mm” as stated on the datasheet, there is only a 0.01604 mm or 16.04 microns difference. In addition, when you look more closely at the flatness value of the part, the flatness is particularly good (max deviation is 0.0005” or 0.0127 mm).

Test 1 is a great test to demonstrate the accuracy and alignment performance of the Space Spider handheld 3D scanner even when 3D scanning tricky parts such as a 1-2-3 Block.

Test 2

Linear Accuracy of Artec Space Spider

(Long Straight Object)

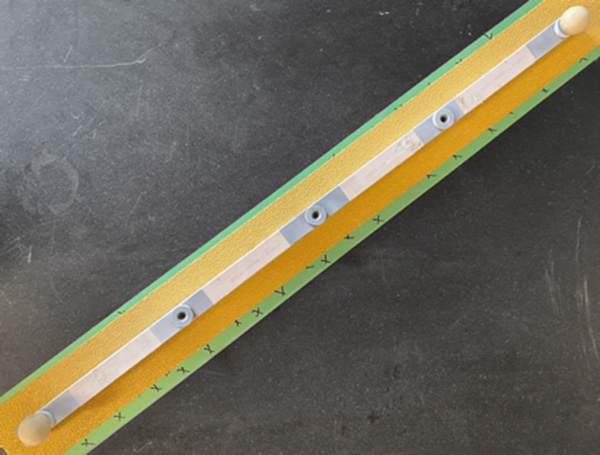

In this test, we were conducting a linear accuracy test with the system. A ballbar is a telescoping bar with precision balls at each end. It is often used in testing the accuracy of a measurement device (in this case, the Artec Space Spider) because it has a known distance. For this test, the true value of the distance between the center points of the two balls is 24.0195”.

What makes 3D scanning a ballbar of 24” so difficult to scan?

Because we’re not merging the scans into one complete model, there were a few challenges we would be facing. When 3D scanning a part that is long in length, it can negatively affect scan accuracy. As a result, this test was devised to see how good the Artec Space Spider 3D scanner is at aligning scans in a straight line for an object this long. As in the first test, the lack of unique features and geometry made accurate alignment challenging.

Criteria For This Test

Because we’re not creating a complete 3D model of the part (we’re only taking scans in a linear direction), we used external geometry by introducing 40-grit sandpaper and marked a few areas with an x using a black marker to add more texture to the registration process.

Due to the way the Artec Space Spider scans and it’s a handheld 3D scanning system, we wanted to look at the accuracy of its frame to frame alignment across a given area.

Testing Procedure

This test was conducted on 6 occasions using 3 different people, across several days at different times. Scan processing procedure was the same each time for repeatability. We located the center points of the spheres in each scan sample and measured the distance between them (“Total Distance”) and put them in an Excel spreadsheet.

Test Results: Space Spider GR&R for 24” Ballbar

| Ballbar GR&R 24” | Total Distance | Distance From Avg | Distance from Nominal (Total Distance – 24.0195) |

|---|---|---|---|

| JPBB1 | 24.0230 | 0.0033 | 0.0035 |

| JPBB2 | 24.0190 | -0.0007 | -0.0005 |

| AABB1 | 24.0170 | -0.0027 | -0.0025 |

| AABB2 | 24.0220 | 0.0023 | 0.0025 |

| PMBB1 | 24.0190 | -0.0007 | -0.0005 |

| PMBB2 | 24.01800 | -0.0017 | -0.0015 |

| Standard Deviation | 0.0023 | 0.0023 | 0.0023 |

| Max Deviation | 24.0230 | 0.0033 | 0.0035 |

| Average | 24.0197 | 0.0000 | 0.0002 |

| Max From Average | 0.0033 | 0.0033 | 0.0033 |

* Nominal = True center to center measurement is 24.0195”

Findings

As mentioned earlier, the true center to center value is actually 24.0195”. When we subtract the Total Distance from Nominal, we see that the max deviation is 0.0035” (0.0889 mm).

Taking Into Consideration Thermal Expansion Of The Part: In our office, we have a relatively large temperature fluctuation throughout the day where the testing was being conducted. We conducted testing over different times during several days. Due to the physical changes in the part due to temperature fluctuations (shrinkage or growth), we have to account for thermal compensation for the numbers we collected so we don’t overtax on the accuracy of the 3D scanning system.

| All Values in INCHES | |

|---|---|

| Thermal Expansion | ~ +/-0.00075″ Total Range: 0.0015 |

| Standard Deviation | 0.0008 |

| Max Deviation | 0.0020 (0.0035 – 0.0015) |

| Max From Average | 0.0018 |

When we account for thermal expansion of the part, the max deviation is 0.0020” (0.0508mm). This is very close to specifications of the accuracy of the Space Spider (close to “up the 0.05mm” as stated on the datasheet). This is even when we put the Space Spider under extreme testing to scan a part that’s two feet in length. This is usually longer than the field of view that this handheld 3D scanner would normally scan which is very impressive to see.

Video Recap

Here’s a video recap of the tests and the results:

Takeaway

If we set up our part correctly and we make sure we have enough geometry to create an accurate alignment across our part, we can get a very accurate scan file out of the Artec Space Spider. In our two tests, the handheld 3D scanner performed well, even under these difficult tests that were not normally what you would scan in your everyday scanning.

Sometimes you can learn a lot from just 3D scanning different parts and see what types of 3D scanning results you can achieve. It’s especially useful to scan parts with known measurements (i.e. 1-2-3 block or ballbar) to test to make sure your scanner is running at optimal performance. If you’ve done testing and find that your scanner is not performing correctly the way it should, it’s a sign that you need to investigate to see what external factors are the cause of the issue before seeing if the actual equipment is the issue (user error vs. equipment error).

It’s important to get familiar with your equipment in order to better understand how it performs under various conditions. The quality of the data you generate is only good if the user of the 3D scanner knows how to use the equipment properly.

Got Questions?

If you have any questions about the tests or the accuracy of any of the Artec 3D scanner systems, please feel free to contact us. We’ll be happy to answer your questions.

– – –

Reference:

- CNC Philosophy, 1-2-3 Blocks